The sheet metal forming stamping process is an important metal processing method, which can form the metal sheet into the desired shape and structure through pressure.

Part 1: Overview of Sheet Metal Forming Stamping Process

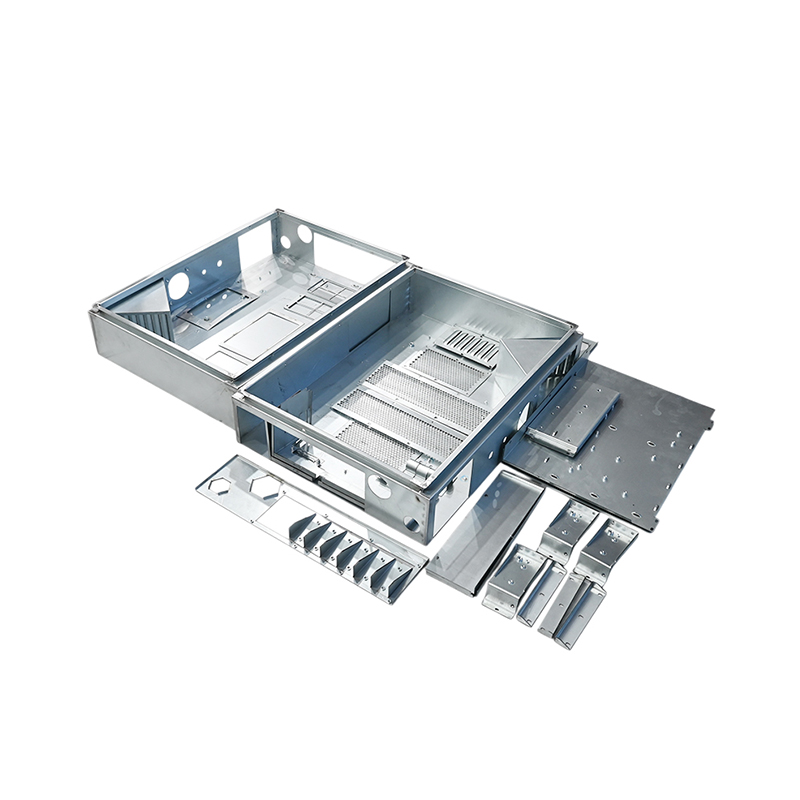

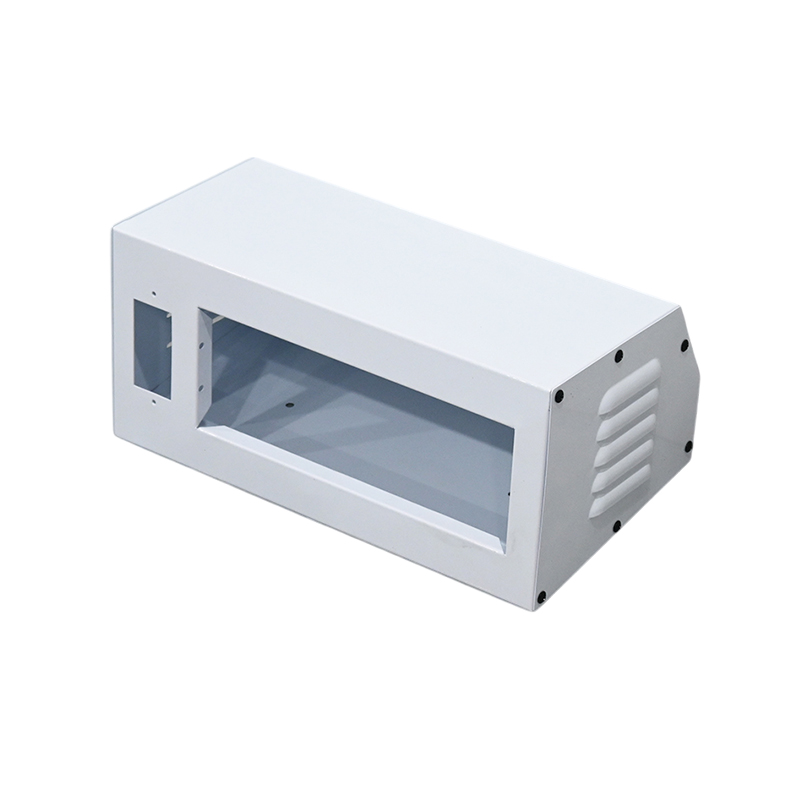

Sheet metal forming stamping process is a processing method that forms a metal sheet into a desired shape and structure through pressure and a mold. It is widely used in automobile manufacturing, electronic equipment, home appliances, construction and aerospace and other fields. The sheet metal forming stamping process is efficient, precise and repeatable, making it the processing method of choice for many manufacturing industries.

Part II: Key elements of sheet metal forming stamping process

1. Material selection: In the sheet metal forming stamping process, the selection of materials is very important. Different materials have different forming characteristics and mechanical properties, so it is necessary to choose the appropriate material according to the requirements of the product. Common sheet metal materials include cold-rolled steel, stainless steel, aluminum alloy, etc. The thickness of the material also affects the ease and formability of the forming process.

2. Die design: Die is one of the key elements in sheet metal forming stamping process. Excellent mold design can ensure the stability of the forming process and product quality. The design of the mold should take into account factors such as the flexibility of the material, the distribution of strength, and the dimensional accuracy after forming. At the same time, reasonable mold material selection and surface treatment can also prolong the service life of the mold.

3. Forming process control: The control of the forming process is very important to obtain high-quality sheet metal products. Parameters such as pressure, speed and temperature should be well controlled during the forming process to avoid stretching, cracking or tearing of the material due to excessive or insufficient pressure. Precise forming process control can ensure the dimensional accuracy and surface quality of the product.

4. Cooling and post-processing: After sheet metal forming and stamping, the heat generated will affect the performance and dimensional stability of the material. Therefore, proper cooling and post-processing processes are the key to ensure the quality of the finished product. The cooling rate and temperature should be adjusted according to the properties of the material to avoid stress and deformation.

Part III: Comparison of sheet metal forming stamping process with other metal processing methods

1. Sheet metal forming stamping process vs. traditional forging: Compared with traditional forging, sheet metal forming stamping process has higher production efficiency and forming accuracy. Forging is generally suitable for large and complex components, while sheet metal forming and stamping processes are more suitable for small and medium-sized products. In addition, the sheet metal forming stamping process can save materials, reduce weight, and adapt to the trend of lightweight.

2. Sheet metal forming stamping process vs. laser cutting: Laser cutting is suitable for cutting sheet metal materials and cutting parts, while sheet metal forming stamping process can complete the forming of complex parts in one forming process. Laser cutting has high precision, but the cost is high; sheet metal forming stamping process has more advantages in mass production.

3. Sheet metal forming stamping process vs. bending processing: bending processing is often used to bend flat sheet metal parts into complex shapes, while sheet metal forming stamping process can form flat sheet metal at one time. Bending processing is more suitable for thinner sheet metal materials, while for thick sheets and large-sized parts, sheet metal forming stamping process has more advantages.

Part IV: The Importance of Sheet Metal Forming Stamping Process

Sheet metal forming stamping process plays an important role in modern manufacturing. Its high efficiency, precision and repeatability make it widely used in mass production. The sheet metal forming stamping process can realize the rapid forming of complex parts, reduce the number of processing times and procedures, and reduce production costs. At the same time, the sheet metal forming and stamping process also promotes the lightweight design of the product and meets the continuous improvement requirements for product quality and performance.

The key to the sheet metal forming stamping process lies in material selection, mold design, forming process control, cooling and post-processing, etc. The rational application and optimization of these key elements directly affect the forming quality and efficiency of the sheet metal forming stamping process.

EN

EN  English

English Español

Español Detusch

Detusch