Custom High Quality Sheet Metal Mounting Bracket Manufacturer

In the realm of manufacturing and construction, the term "Sheet Metal Mounting Bracket" holds significant importance. This versatile component is a staple in various industries, from automotive to aerospace, due to its adaptability and strength. What exactly is a Sheet Metal Mounting Bracket, and why is it so widely used? Let's delve into the intricacies of this essential piece of hardware.

Understanding the Sheet Metal Mounting Bracket

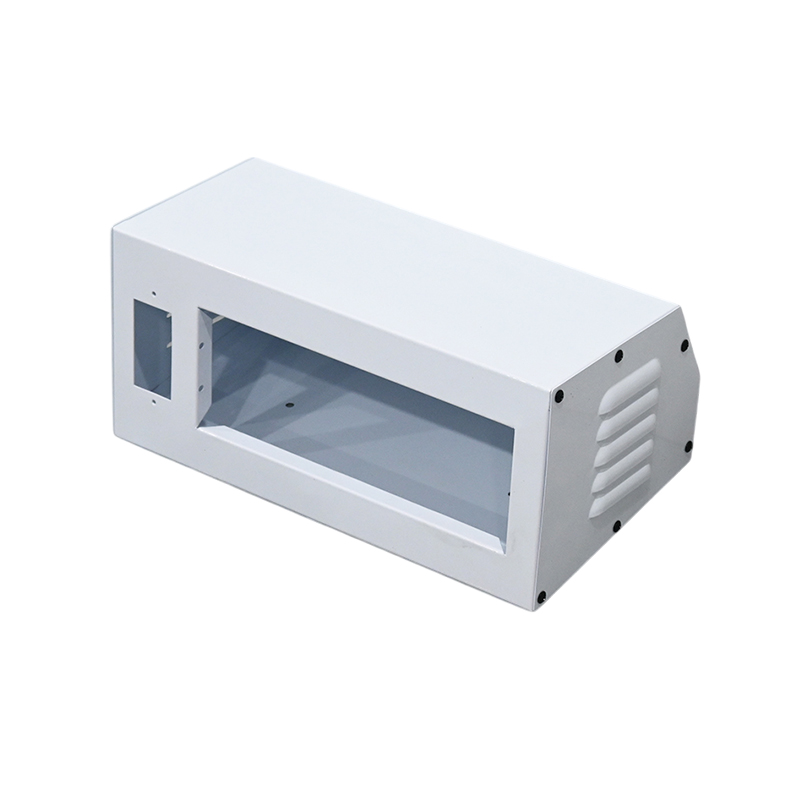

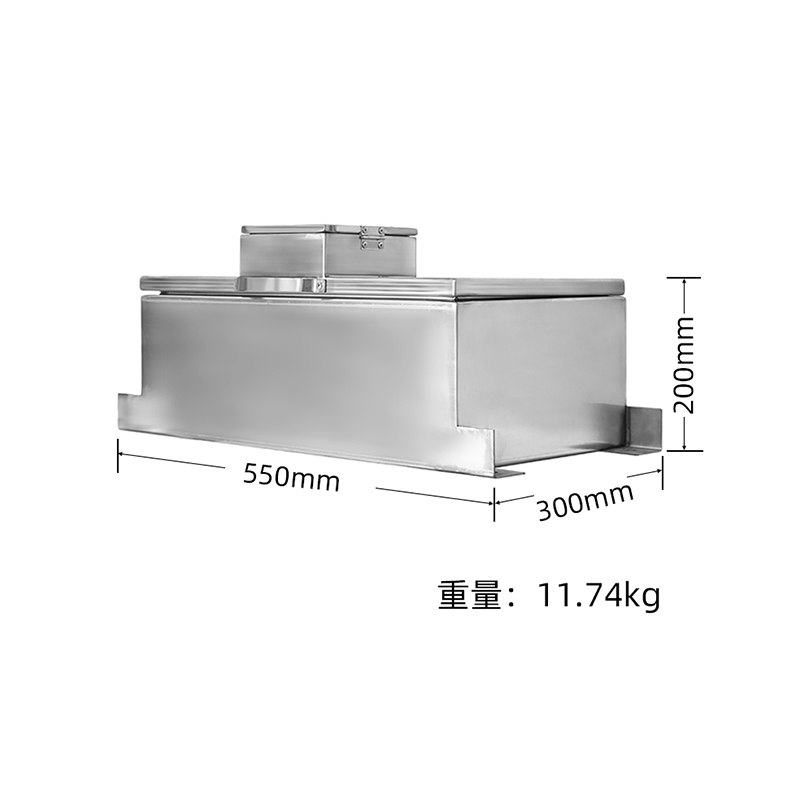

A Sheet Metal Mounting Bracket is a supportive structure made from sheet metal, designed to hold, secure, or position another object. These brackets are engineered to withstand various forces and weights, making them indispensable in applications where stability and durability are paramount. The term "Sheet Metal Mounting Bracket" encapsulates a broad range of shapes and sizes, each tailored to specific use cases.

Applications: A Cross-Industry Staple

The versatility of Sheet Metal Mounting Brackets is evident in their widespread applications. In the automotive industry, they are used to mount engines, batteries, and various other components within the vehicle's framework. In construction, they secure pipes, beams, and electrical conduits, ensuring structural integrity and safety. The aerospace industry relies on these brackets for mounting control surfaces and other critical components within aircraft. Each application demands a specific type of Sheet Metal Mounting Bracket, showcasing their adaptability.

Design Considerations: Material and Structural Integrity

When designing a Sheet Metal Mounting Bracket, several factors must be considered to ensure its performance and longevity. The choice of material is crucial; steel and aluminum are common choices due to their strength and malleability. The design must also account for the weight and size of the object it will support, as well as the environmental conditions it will face. Engineers must calculate the stress and strain that a Sheet Metal Mounting Bracket will endure, ensuring it can bear the load without failure.

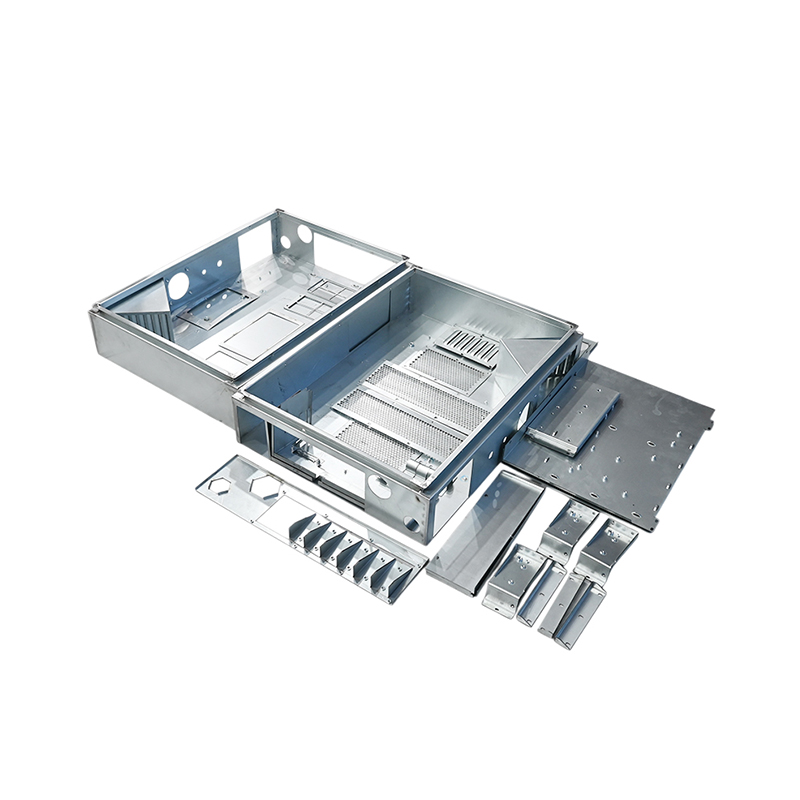

Manufacturing Process: From Concept to Creation

The manufacturing process of a Sheet Metal Mounting Bracket involves several stages. Initially, the design is created using Computer-Aided Design (CAD) software, which allows for precise measurements and visualization. Following the design, the sheet metal is cut using techniques such as laser cutting or stamping to achieve the desired shape. Bending and folding processes then shape the metal into the final bracket form. Quality control is integral throughout manufacturing, with inspections to ensure that each Sheet Metal Mounting Bracket meets the specified tolerances and performance criteria.

Maintenance and Durability: Ensuring Longevity

Proper maintenance is key to extending the life of a Sheet Metal Mounting Bracket. Regular inspections can identify any signs of wear or corrosion, allowing for timely repairs or replacements. The choice of material can also impact the longevity of the bracket; materials like stainless steel offer increased resistance to corrosion, which is particularly important in outdoor applications or in environments with high humidity.

Future Trends: Evolving with Technology

The Sheet Metal Mounting Bracket industry is not immune to the technological advancements sweeping through manufacturing. Innovations in materials science are to the development of lighter, stronger metals that can be used in Sheet Metal Mounting Brackets, reducing weight without compromising strength. Additionally, the integration of smart sensors within brackets can provide real-time monitoring of stress and strain, enhancing safety and reliability.

In conclusion, the Sheet Metal Mounting Bracket is a critical component in various industries, providing essential support and stability. Its design and application are governed by a multitude of factors, from material selection to the specific demands of its environment. As technology continues to evolve, so too will the Sheet Metal Mounting Bracket, ensuring its continued relevance and importance in the world of manufacturing and construction.

EN

EN  English

English Español

Español Detusch

Detusch