The global market for sheet metal cabinets has been experiencing significant growth, driven by the demand for durable and efficient storage solutions in various industries. China, with its robust manufacturing capabilities and cost-effective production processes, has emerged as an exporter of these cabinets. This article delves into the strategies and better practices for optimizing the supply chain of china sheet metal cabinets made in China, ensuring that businesses can deliver high-quality products to their customers while maintaining competitive pricing.

The Importance of Supply Chain Optimization:

An optimized supply chain is crucial for any business looking to stay ahead in the competitive global market. For china sheet metals made in China, this involves streamlining the manufacturing process, reducing lead times, and ensuring that higher quality standards are met. By focusing on these areas, companies can improve their bottom line and customer satisfaction.

Manufacturing Excellence:

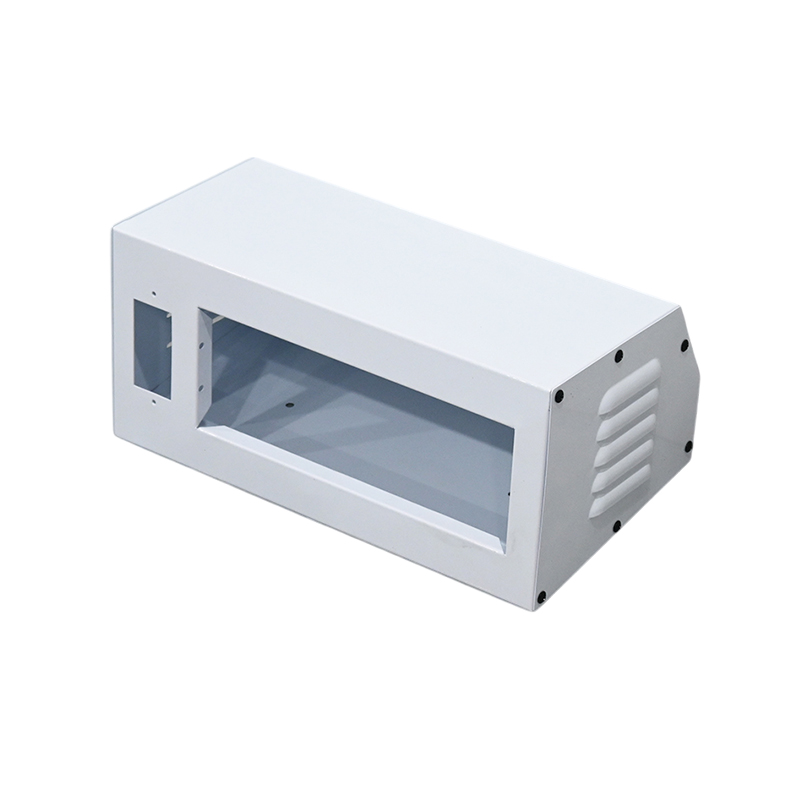

China's manufacturing sector is known for its ability to produce high-quality china sheet metal cabinets at a lower cost than many other countries. This is due to a combination of factors, including advanced technology, skilled labor, and efficient production processes. To maintain this competitive edge, manufacturers must continually invest in the latest machinery and training programs to ensure their workforce is equipped with the necessary skills to produce top-tier products.

Quality Control Measures:

Implementing strict quality control measures is essential to ensure that every china sheet metal cabinet made in China meets international standards. This includes regular inspections at various stages of production, from the sourcing of raw materials to the final assembly. By doing so, manufacturers can identify and rectify any issues before the product reaches the customer, reducing the risk of returns and negative reviews.

Logistics and Distribution:

The logistics and distribution of china sheet metal cabinets made in China require careful planning to minimize costs and delivery times. This involves selecting reliable shipping partners, optimizing routes, and utilizing modern tracking systems to monitor the progress of each shipment. Additionally, businesses should consider establishing regional distribution centers to reduce transit times and offer faster delivery options to their customers.

Sustainability Initiatives:

As environmental concerns become increasingly important to consumers, businesses that prioritize sustainability are likely to see a competitive advantage. For china sheet metal cabinets made in China, this can include using recycled materials, implementing energy-efficient production processes, and reducing waste throughout the manufacturing cycle. By adopting these practices, companies can not only improve their environmental footprint but also appeal to a growing market of eco-conscious consumers.

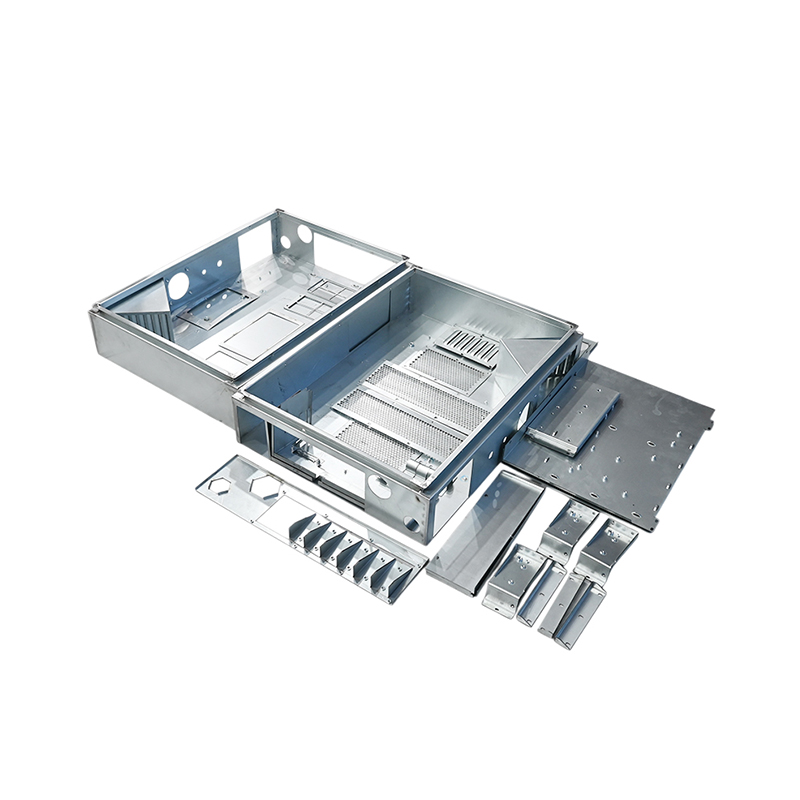

Customization and Personalization:

In today's market, customers are looking for products that are tailored to their specific needs. For china sheet metal cabinets made in China, this means offering a range of customization options, from size and color to additional features such as locking mechanisms or adjustable shelves. By providing these options, manufacturers can cater to a wider audience and differentiate themselves from competitors.

Technology Integration:

Incorporating advanced technology into the manufacturing process can significantly improve the efficiency and quality of sheet metal cabinets made in China. This includes the use of computer-aided design (CAD) software for precision engineering, automated machinery for faster production, and data analytics for better inventory management. By embracing these technologies, businesses can stay ahead of the curve and offer excellent products to their customers.

Risk Management:

The supply chain for china sheet metal cabinets made in China is subject to various risks, including fluctuations in raw material prices, geopolitical tensions, and currency exchange rates. To mitigate these risks, businesses should implement robust risk management strategies, such as diversifying their supplier base, maintaining healthy cash reserves, and staying informed about global economic trends.

Conclusion:

Optimizing the supply chain for china sheet metal cabinets made in China is a multifaceted process that requires a commitment to quality, efficiency, and innovation. By focusing on manufacturing excellence, implementing quality control measures, streamlining logistics, prioritizing sustainability, offering customization options, integrating technology, and managing risks, businesses can ensure they are well-positioned to meet the growing demand for these versatile and durable storage solutions. As the global market continues to evolve, those who can successfully navigate these challenges will be the ones to reap the rewards of a thriving industry.

EN

EN  English

English Español

Español Detusch

Detusch